Tube Mill

You are here: Home>Tube Mill

Tube Mill – Complete Pipe Line Solutions

At TENGDI, we deliver turnkey solutions for welded steel pipe production.

Our tube mill machines and auxiliary equipment are engineered to work seamlessly as a production line, helping manufacturers achieve high efficiency, low downtime, and precision pipe quality.

Whether you need ERW tube mills, customized pipe making machines, or auxiliary systems, TENGDI is your trusted partner.

Tube Mill Specifications

Our tube mill collection offers a wide range of machines tailored to different pipe sizes, thicknesses, and materials. From high-speed ERW (Electric Resistance Welded) tube mills to heavy-duty lines for structural pipes, we provide customizable solutions that meet industry-specific requirements.

Tube Mill Production Line Overview

Entry Section

Steel coils are loaded with a coil car and smoothly fed into the line by a hydraulic uncoiler. Leveling equipment ensures strip flatness and tension, while shear and butt welders join coil ends seamlessly. An accumulator stores material to keep production continuous, and guiding devices ensure precise strip alignment for forming.

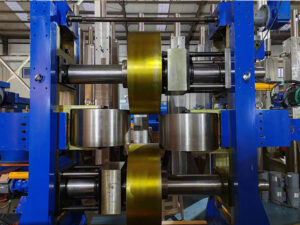

Forming & Welding Section

The strip is gradually shaped into a round tube through forming stands, then welded using a high-frequency welder. Internal and external bead scarfing systems remove weld flash, while seam tracking and inline monitoring guarantee consistent weld quality and accuracy.

Sizing & Cooling Section

After welding, tubes are precisely sized to required dimensions with sizing mills and straightening machines. Cooling systems stabilize the tube structure, and measuring devices ensure accuracy, preparing pipes for cutting and finishing.

Cutting & Run-Out Section

High-speed flying saws or cold cutting systems cut tubes to exact lengths. Finished pipes are transferred onto run-out tables or conveyors, ensuring smooth handling and high production efficiency.

Finishing, NDT & Packing

Pipes undergo end-facing, chamfering, and non-destructive testing, such as ultrasonic or eddy current inspection, to verify quality. Products are then marked, bundled, strapped, and labeled for traceable, ready-to-ship deliveries.

Why Choose TENGDI Machinery for Your Tube Mill Needs

At TENGDI Machinery, we bring together decades of engineering expertise and innovative technology to deliver fully customized tube mill solutions. Every piece of equipment is built for durability, accuracy, and high-speed production, with advanced automation features for maximum efficiency. From design and manufacturing to installation, operator training, and long-term after-sales support, we provide a one-stop solution that ensures your production line performs at its best.

Applications of Tube Mill Products

Pipes manufactured on TENGDI tube mill lines are widely used in:

Structural and construction projects

Automotive components and chassis systems

Oil, gas, and water pipeline infrastructure

Furniture manufacturing and home appliances

Industrial machinery and mechanical parts

Tube Mill FAQ

Q1: What is a tube mill machine used for?

A tube mill machine is designed to manufacture welded steel pipes by forming, welding, sizing, cutting, and finishing steel strips into pipes of various diameters and wall thicknesses.

Q2: What auxiliary equipment is included in a tube mill line?

Auxiliary equipment includes hydraulic uncoilers, coil cars, strip leveling and edge trimming machines, high-frequency welders, ferrite impeders, cooling systems, sizing stands, flying saws, end-facing equipment, NDT systems, and packaging machines.

Q3: Can TENGDI Machinery provide customized tube mill solutions?

Yes, we design and deliver complete tube mill production lines tailored to your specifications, ensuring optimal efficiency and output for your application.

Q4: How is pipe quality guaranteed?

We integrate precision forming systems, advanced welding technology, automated NDT equipment, and strict quality control processes throughout production to ensure every pipe meets industry standards.

Products

- O.D.457mm FFX ERW Tube Mill

- 34mm*6.5mm Pipe Mill

- Roller Quick Change System Tube Mill

- Direct Forming Technology Square Tube Mill

- TD 38 Tube Mill(O.D.12-38mm)

- TD 50 Tube Mill(O.D.25-63mm)

- TD 76 Tube Mill(O.D.32-89mm)

- TD 114 Tube Mill(O.D.42-119mm)

- TD 127 Tube Mill(O.D.42-127mm)

- TD 219 Tube MIll(O.D.89-219mm)

- TD 273 Tube MIll(O.D.114-273mm)

- TD 325 Tube MIll(O.D.127-325mm)

- Slitting Line

- Cut to Length Line

- Cold Roll Forming Machine