Steel Pipe Making Machine

Product Detail

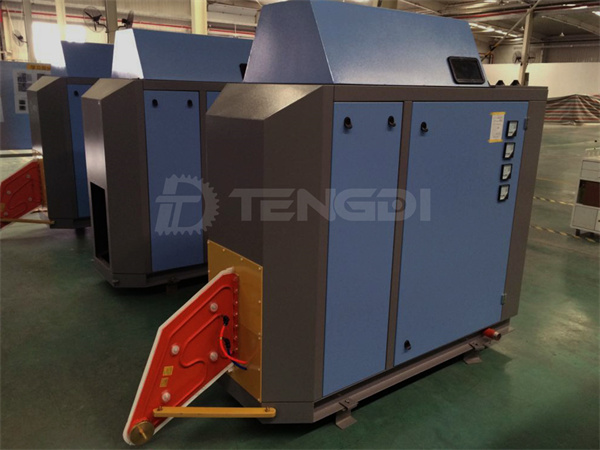

Steel Pipe Making Machine: Comprehensive Overview and Customized Solutions

A steel pipe making machine, also known as a tube mill, is a specialized industrial machine designed for the efficient production of steel pipes and tubes. This machinery is essential for industries that require high-strength, durable pipes for various applications, such as construction, automotive, oil and gas, and more. Our steel pipe making machines are renowned for their advanced technology, high precision, and reliability. We also provide customized solutions tailored to meet the specific requirements of different factories, ensuring that our clients receive machinery that fits their unique production needs.

Steel Pipe Making Machine Specifications

| Pipe Line Size | Round Pipe | Square/Rectanglar | Pipe Thickness | Producing Speed |

| TD20 | φ8-φ12 | 6*6-10*10 | 0.3-1.2 | 80-≥120 |

| TD32 | φ10-φ32 | 8*8-25*25 | 0.4-2.0 | 80-≥120 |

| TD50 | φ12-φ50 | 10*10-40*40 | 0.5-3.0 | 80-≥120 |

| TD60 | φ20-φ76 | 15*15-50*50 | 0.8-3.5 | 60-≥120 |

| TD76 | φ25-φ76 | 20*20-60*60 | 1.2-4.0 | 60-≥100 |

| TD114 | φ45-φ114 | 35*35-90*90 | 1.5-4.5 | 40-≥90 |

| TD165 | φ60-φ165 | 50*50-130*130 | 2.0-6.0 | 30-≥50 |

| TD219 | φ76-φ219 | 60*60-170*170 | 3.0-8.0 | 25-≥50 |

| TD273 | φ89-φ273 | 70*70-210*210 | 3.0-10.0 | 20-≥50 |

| TD325 | φ114-φ325 | 90*90-250*250 | 4.0-12.7 | 15-≥40 |

| TD406 | φ165-φ406 | 130*130-320*320 | 5.0-16.0 | 15-≥30 |

| TD508 | φ219-φ508 | 170*170-400*400 | 5.0-16.0 | 15-≥30 |

Auxiliary Products in the Steel Pipe Making Machine Production Line

A steel pipe making machine production line is supported by a range of auxiliary products, each contributing to the overall efficiency and precision of the manufacturing process. Below is a list of the auxiliary products and their respective functions:

Uncoiler: The uncoiler holds and unwinds the steel strip coils, ensuring a smooth feed into the machine. It provides stable tension and alignment, which are crucial for maintaining consistent pipe dimensions.

Shear and End Welder: This equipment is responsible for cutting the steel strips to the desired length and welding the ends together. It enables continuous production by minimizing downtime during coil changes.

Strip Accumulator: The strip accumulator stores steel strips, allowing the production process to continue uninterrupted during coil changes. This ensures high productivity and efficiency.

High Frequency Solid State Welder: This welder uses high-frequency induction to weld the steel strips, creating a strong and seamless joint. It ensures precise control of welding parameters, resulting in high-quality welds.

Flying Saw: The flying saw cuts the steel pipes to the required length without stopping the production line. It synchronizes with the speed of the pipe, ensuring clean and accurate cuts.

Pipe Hydro Testing Machine: This machine tests the steel pipes for leaks and strength under high pressure. It ensures that the pipes meet industry standards and are safe for use in demanding applications.

Pipe End Facing Machine: This equipment processes the ends of the steel pipes, ensuring smooth and precise edges. It is essential for preparing pipes for subsequent processes like threading or coupling.

Pipe Packing Machine: The pipe packing machine bundles and packs the finished steel pipes for safe and efficient transportation. It ensures that the pipes are securely packed, minimizing the risk of damage during transit.

Each auxiliary product in the steel pipe making machine production line offers unique advantages, from enhancing production efficiency to ensuring the quality and precision of the final product.

Advantages of Our Steel Pipe Making Machine

High Yield: Our steel pipe making machines are designed to maximize production output, ensuring high yield with minimal waste.

Customization: With a professional design team, we provide tailored solutions to meet all customer needs. Whether it’s a specific pipe dimension, material requirement, or production capacity, we can create the perfect machine for your operation.

Advanced Technology: We incorporate the latest technological advancements in our machines, ensuring precision, reliability, and ease of operation.

Durability and Reliability: Our machines are built with high-quality materials and components, ensuring long service life and consistent performance even under heavy-duty conditions.

Steel Pipe Production Process

The steel pipe production process involves several key steps:

Uncoiling: The steel strip is unwound from the coil and fed into the machine.

Shearing and Welding: The steel strip is cut to the desired length and welded together to form a continuous strip.

Forming: The continuous strip is passed through a series of rollers that shape it into a round tube.

Welding: The edges of the formed tube are welded together using a high-frequency solid-state welder.

Sizing: The welded tube is passed through additional rollers to achieve the final desired dimensions.

Cutting: The finished pipe is cut to the required length using a flying saw.

Testing and Inspection: The pipes undergo hydro testing and inspection to ensure they meet quality standards.

End Facing and Packing: The pipe ends are processed, and the pipes are packed for shipment.

Our Services for Your Steel Pipe Making Machine Purchase

When you purchase a steel pipe making machine from us, you can expect comprehensive services to ensure a smooth and successful installation and operation:

On-Site Installation and Debugging: We provide experienced engineers to assist with the on-site installation and debugging of the machinery, ensuring it operates at optimal efficiency from day one.

Lifetime Warranty: We offer a lifetime warranty on our machines, giving you peace of mind that your investment is protected.

After-Sales Support: Our dedicated support team is always available to assist with any technical issues or maintenance needs.

By choosing our steel pipe making machine, you’re not only investing in high-quality machinery but also in a partnership with a company committed to your success. We are here to support you every step of the way, from initial consultation to after-sales service.

Products

- O.D.457mm FFX ERW Tube Mill

- 34mm*6.5mm Pipe Mill

- Roller Quick Change System Tube Mill

- Direct Forming Technology Square Tube Mill

- TD 38 Tube Mill(O.D.12-38mm)

- TD 50 Tube Mill(O.D.25-63mm)

- TD 76 Tube Mill(O.D.32-89mm)

- TD 114 Tube Mill(O.D.42-119mm)

- TD 127 Tube Mill(O.D.42-127mm)

- TD 219 Tube MIll(O.D.89-219mm)

- TD 273 Tube MIll(O.D.114-273mm)

- TD 325 Tube MIll(O.D.127-325mm)

- Slitting Line

- Cut to Length Line

- Cold Roll Forming Machine