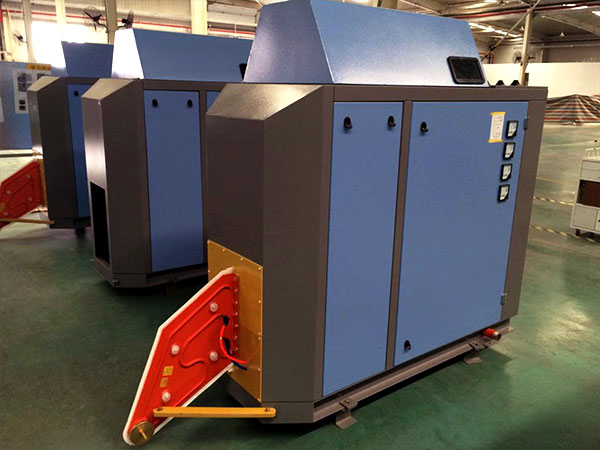

High Frequency Solid State Welder

You are here: Home>Solid State Welder>High Frequency Solid State Welder

Product Detail

High-Frequency Solid State Welder Definition:

A solid state welder is a welding machine that joins materials without melting them, using pressure and sometimes heat to create a solid-state bond.

High-frequency solid state welders use high-frequency electrical energy (usually in the range of 100-800 kHz) to create welds between two edges of a strip or sheet material.

Quick Details

1. The welding speed is fast, and the production capacity is high. Compared to other similar high-frequency welders, it significantly saves energy.

2. The high-frequency welder’s output ripple is less than 1%, resulting in aesthetically pleasing and consistently high-quality weld seams.

3. The inverter side’s PSM pulse shielding technology ensures impedance matching of the welder, guaranteeing stable power output. It accommodates a wide range of steel pipe welding applications and offers both induction and contact welding options.

4. The solid-state high-frequency welder features comprehensive protection functions, ensuring reliable operation and a low failure rate.

High-Frequency Solid State Welder Features:

- Efficiency: Provides efficient and rapid heating of the weld area.

- Control: Offers precise control over welding parameters such as power, frequency, and duration.

- Quality: Ensures consistent weld quality and integrity.

- Adaptability: Can weld a variety of materials including carbon steel, stainless steel, and non-ferrous metals.

- High Speed: Capable of high-speed welding suitable for continuous production lines.

- Energy Efficiency: Operates at high efficiency with minimal energy loss.

- Minimal Distortion: Produces welds with minimal heat-affected zones and distortion.

Scope of Application

High-frequency solid state welders are versatile machines used in various industrial scenarios where precise and efficient welding of metals is required.

Primarily used for the straight seam welding of various types of pipes, including low carbon steel, high-strength steel, and alloy steel, as well as round, square, and rectangular steel tubes.

Tube and Pipe Manufacturing:

- Straight Seam Welded Pipes: Used extensively in tube mills to weld longitudinal seams of pipes made from metals such as carbon steel, stainless steel, and alloys.

- Profile and Structural Shapes: Welding of profiles and structural shapes used in construction and manufacturing.

Automotive Industry:

- Exhaust Systems: Welding of exhaust pipes and components where high precision and weld quality are crucial.

- Fuel Tanks: Seam welding of fuel tanks and other components requiring leak-tight welds.

Electronics and Microelectronics:

- Microelectronic Components: Used in microelectronics for bonding semiconductor materials and creating micro-welds with high accuracy and minimal heat impact.

Renewable Energy:

- Solar Panels: Manufacturing of solar panel components where high-efficiency and durability of welds are essential.

- Wind Turbines: Welding of components in wind turbine manufacturing, ensuring strong and durable joints.

Products

- 457mm FFX ERW Tube Mill

- 34mm*6.5mm Pipe Mill

- Roller Quick Change System Tube Mill

- Large Diameter Direct Forming Square Tube Mill

- TD 38 Tube Mill(12-38mm)

- TD 50 Tube Mill(25-63mm)

- TD 76 Tube Mill(32-89mm)

- TD 114 Tube Mill(42-119mm)

- TD 127 Tube Mill(42-127mm)

- TD 219 Tube MIll(89-219mm)

- TD 273 Tube MIll(114-273mm)

- TD 325 Tube MIll(127-325mm)

- Slitting Line

- Cut to Length Line

- Cold Roll Forming Machine

Related Products

Round Pipe Change to Square Tube Mill

Small Diameter Thick Wall Tube Mill

Roller Quick Change System Tube Mill