TD 50 Tube Mill

Product Detail

50 Tube Mill Quick Details

This equipment is the main machine of the forming section of the tube mill line. it can produce round tubeswith conventional diameters of 25mm-63mm and corresponding square tubes and rectangular tubes. Thisequipment is a non-standard customized product, lf you have special size reguirements, please contact us.

| Manufacture | Tengdi Machinery | Name | TD-50 Tube Mill |

| Type | HF Solid state steel pipe welding production line | Line speed | ≤120m/min |

| Round tube size | Φ25- Φ63mm(3/4″-2″) | Round tube thickness | 0.6 – 3.0 mm |

| Square & pipe size | 25*25-70*70mm | Square & rectangular pipe thickness | 0.6 – 3.0 mm |

| Rectangular tube size | 20*30-40*60 | Rectangular tube thickness | 0.6 – 3.0 mm |

| Pipe material | HR CR Carbon steel/Galvanized steel | Forming method | Round tube to square tube/Directly formed into square tube |

50 tube mill features

Advanced design concepts:We have advanced design concepts and aim to meet all design reguirements ofcustomers and deliver easy-to-use and practical equipment from the customer’s perspective.

High quality tube mill frame material:We use cast steel raw materials, and we personally control everyprocess, including the selection of raw materials.To ensure the durability of the tube mill.

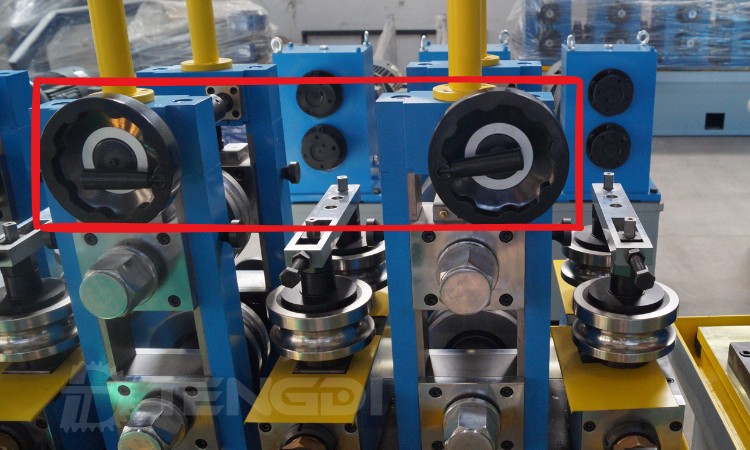

Tube mill roller adjustment method:This equipment uses warm gear and warm to adjust the rolls, and thedistance between the rolls at both ends can be controlled by operating only one side,Save time and improveproductivity.

50 tube mill supporting equipment

3.5T cone uncoiler

For the 50 tube mill machine unit, we adopt a double-cone uncoiling method, with an uncoiling weight of3.5T. The rotation and expansion and contraction of the cone head are controlled by hydraulic pressure. Theslewing bearing design is more stable, and the baffle design prevents the steel coil from loosening.

Strip accumulator

We use strip accumulator to match the 50 tube mill machine production line, which can fully meet therequirements for storing strip steel and ensure continuous production.

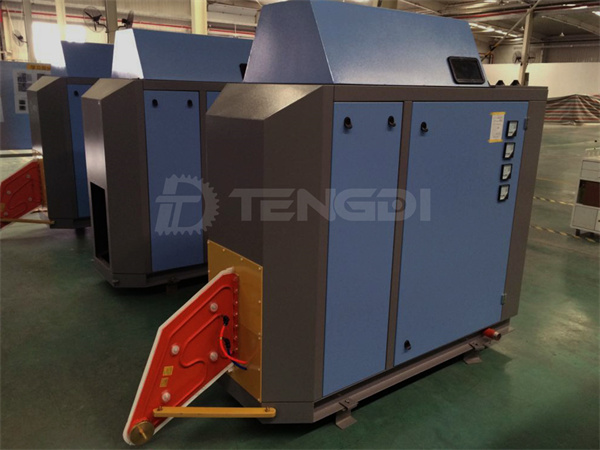

200kw High Frequency Welder

Cold Fly Saw

We use cold fly saws for the steel pipe cutting part to ensure the smoothness of the steel pipe end surface andeliminate the influence of pipe end burrs to the greatest extent. Cold fly saws are also safer than hot fly saws.

Pipe Stacker

Below is the part of our steel pipe palletizer, which can transport steel pipes with a length of 4-8 meters,saving labor costs and improving the efficiency of organizing steel pipes.

Pipe Packing Machine

Finally, the automatic steel pipe packaging system of our 50 tube mill machine production line uses full automatic welded pipe packaging machine equipment, which can realize continuous and uninterruptedautomatic collection, stacking, and automatic bundling of welded pipes online, saving labor.

Products

- O.D.457mm FFX ERW Tube Mill

- 34mm*6.5mm Pipe Mill

- Roller Quick Change System Tube Mill

- Direct Forming Technology Square Tube Mill

- TD 38 Tube Mill(O.D.12-38mm)

- TD 50 Tube Mill(O.D.25-63mm)

- TD 76 Tube Mill(O.D.32-89mm)

- TD 114 Tube Mill(O.D.42-119mm)

- TD 127 Tube Mill(O.D.42-127mm)

- TD 219 Tube MIll(O.D.89-219mm)

- TD 273 Tube MIll(O.D.114-273mm)

- TD 325 Tube MIll(O.D.127-325mm)

- Slitting Line

- Cut to Length Line

- Cold Roll Forming Machine